Did you know that November is traditionally “Quality Month” (品質月間) in Japanese companies?

The practice dates back to the 1950s–60s, when Japan began investing heavily in improving industrial quality. During Quality Month, Japanese companies organize various events, trainings, and campaigns aimed at highlighting the importance of quality and inspiring employees to pursue continuous improvement (kaizen).

The idea has spread globally, and today Quality Month is celebrated in many other countries — including here at Murata Finland.

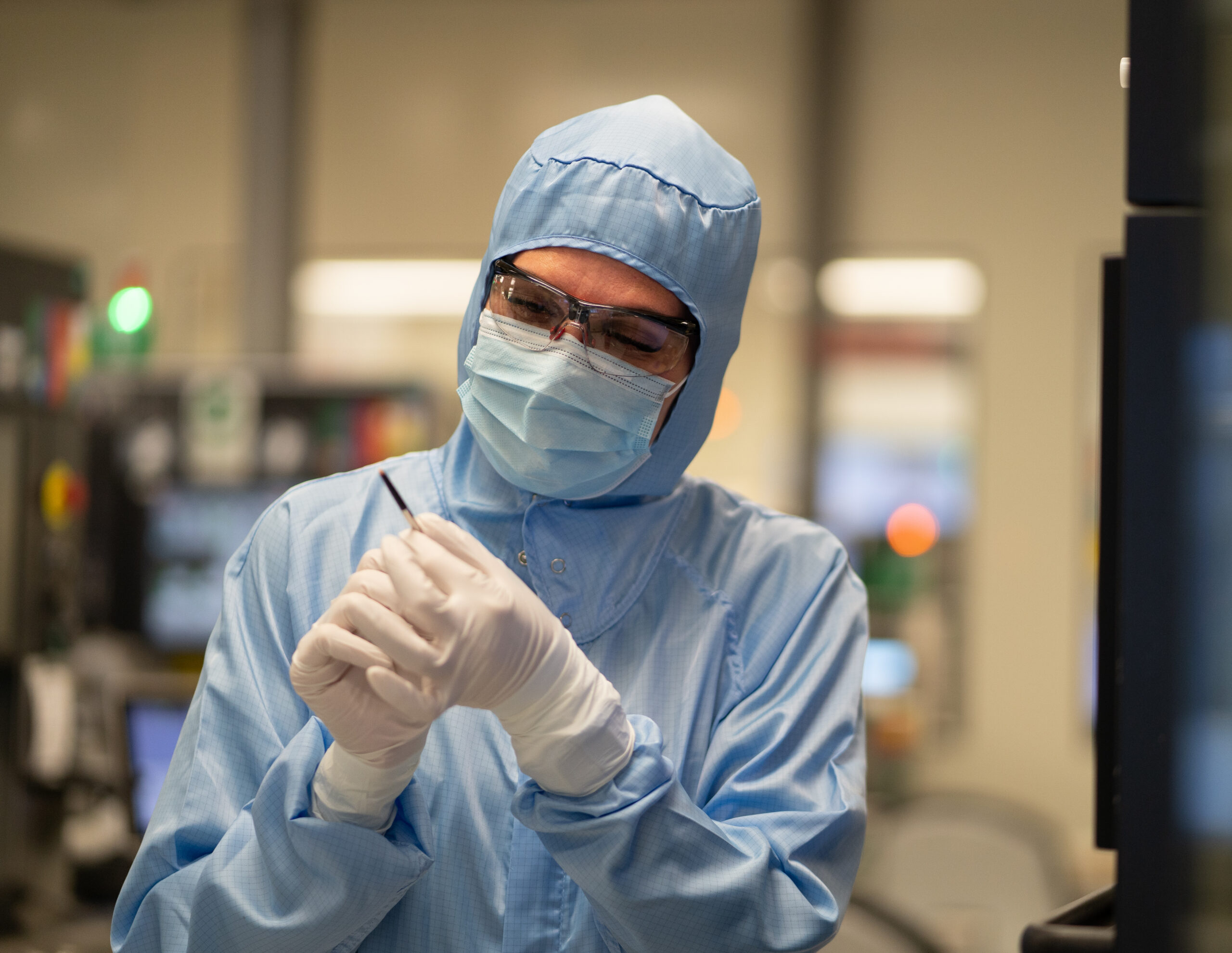

We design and manufacture motion sensors for safety-critical applications such as automotive ADAS systems and pacemakers — so it’s no surprise that we have an uncompromising attitude toward quality. But it’s not just about product quality: Murata’s Quality Month theme, “Quality of Everything,” invited all employees to reflect on quality from different perspectives. We brainstormed new kaizens, tracked down examples of excellent kaizens, and explored quality mysteries solved by our skilled “quality detectives” over the years.

Quality Month has ended, but high-quality work and continuous improvement will go on — one kaizen at a time!